Explosion proof

In many companies the presence of flammable materials can’t be avoided. As a system integrator of the ATOS array we can design your hydraulic system suitable for zones with explosion danger.

The explosion safe component that VAPO utilises comply with the following international rules and regulations:

ATEX, IECEx, EAC

- Group I Gas – mining

- Group II gas and dust

US & Canada

- UL429 , UL1203 en CSA 22.2

PESO

- Petroleum and explosion safety organisation India

MA

- Chinese mining organisation

- SIL2 / SIL3

- According to regulations IEC61508

Safety hydraulics

Pressure vessels with internal overpressure above 0.5 bar always have to be designed according to the PED regulations for pressure equipment (97/23/EG of PED97/23/EC of 2014/68/EU).

Based on the risks certain applications like test benches, presses, kantbank, etc. need extra safety attention when designing the hydraulic system. We advise and implement components that are certified by international recognised certifying authorities.

TÜV certified components based on the Machine regulation 2006/42/EC

- Valves with position detection (direct of piloted)

- Screw cartridges and ISO cartridges with cartridge position detection

IMQ certified components based on PED Regulations 2014/68/UE

- Pressure relief valves

- Hydraulic cylinders & servo cylinders

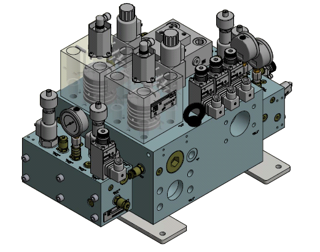

- Hydraulic units

- Hydraulic manifolds

- SIL / PL components

Safety Integrity Level (SIL) & Performance Level (PL) are indicators of the maximum allowable risks in processes that help minimise dangerous situations.

TÜV certified components based on EN IEC 61508 (SIL) and EN ISO 13849 (PL)

- Digital proportional valves

- Servo cylinders with position sensors

We also design specific safety manifolds for vertical presses. Thes are TÜV certified according EN ISO 12622 and EN ISO 13849.

Ohter applications are kantbank, sheet cutting machines, pipe bending machines, etc.

Industries

- Industry

- Infra

- Dredging

- Maritime

- Offshore